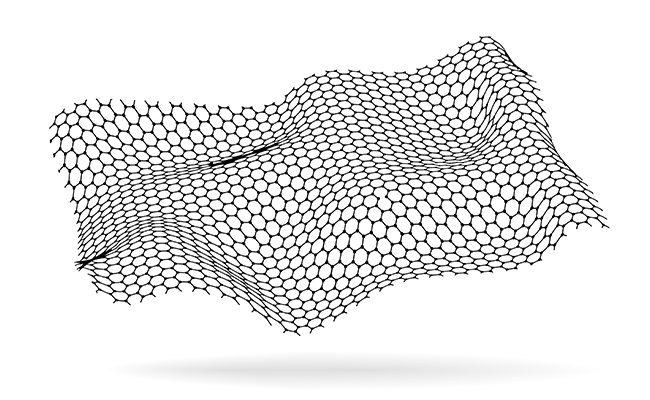

Carbon nanotubes, which are the stretched and tubularized form of the fullerene molecule, have a band structure that varies from metallic to semiconductor properties according to different radius and chiral angles. Graphene, the first 2-dimensional material with a thickness of one atom, was discovered in 2004, and it brought the nanocarbon group a Nobel Prize in 2010 because the electrons on it move like massless particles close to the speed of light. The structure of graphene paves the way for the flexible and transparent construction of next-generation electronic devices such as nano optoelectronics, ultra-sensitive sensors, very fast transistors, etc., as well as enabling existing technology to improve faster and more effectively.

Beyond electronics/optoelectronics, nanocarbon materials represent a groundbreaking field in diverse and versatile applications ranging from energy to functional nanocomposites. R&D studies on nanocarbon materials, which have both military and civilian applications, are carried out intensively within ASELSAN Research Center in order to follow the constantly developing technology and to guide the new generation technology.

.jpg) In the 20th century, polymeric structures discovered with scientific developments have been the subject of many academic and industrial studies and their synthetic production has become widespread. Polymeric materials have replaced conventional materials used in many applications due to their properties. The most common examples are composites, adhesives, optical elements, circuit boards, ballistic products, sensor systems, functional coatings and paints.

In the 20th century, polymeric structures discovered with scientific developments have been the subject of many academic and industrial studies and their synthetic production has become widespread. Polymeric materials have replaced conventional materials used in many applications due to their properties. The most common examples are composites, adhesives, optical elements, circuit boards, ballistic products, sensor systems, functional coatings and paints.

The chemical structure of polymeric materials determines their properties. By controlling the structural factors that affect the application, smart designs can be realized for use in many different applications. In this context, the properties of polymeric materials such as temperature resistance, adhesion, mechanical, dielectric, conductivity and thermoelectricity are among the subjects of our Research Center.

Advanced ceramics, which play a critical role in scientific and technological advances in the world, are materials with a very high added value and a large market share in the global market. Advanced ceramics are especially critical for electronic and opto-electronic applications thanks to their dielectric, electrical and thermal insulating, piezoelectric, superconducting, magnetic and semiconducting properties.

The microstructure, purity and porosity of advanced ceramics determine their optical properties. Therefore, advances in the synthesis and processing techniques of these materials have expanded the application areas of ceramics in optics and photonics. Optical ceramics are used in many different fields such as high-power solid-state lasers, optical domes (windows), lenses, filters, waveguides and scintillators. They are excellent candidates for optical domes due to their high transmittance over a wide spectral range, high hardness, scratch and shock resistance properties. Polycrystalline laser crystals, which have advantages over single crystal lasers such as ease of fabrication, ease of size and no doping concentration limitations, are an important research topic.

.jpg) Additive manufacturing, which was first used on polymer materials, is a technology that emerged as an alternative to traditional production methods because it enables the rapid production of parts with complex geometries. Additive manufacturing method attracts great interest as the manufacturing method of the future in all sectors of the world with its advantages over traditional manufacturing methods. The fact that additive manufacturing technologies create a weight advantage by reducing the number of assembled parts with monolithic production also plays an important role in attracting so much attention.

Additive manufacturing, which was first used on polymer materials, is a technology that emerged as an alternative to traditional production methods because it enables the rapid production of parts with complex geometries. Additive manufacturing method attracts great interest as the manufacturing method of the future in all sectors of the world with its advantages over traditional manufacturing methods. The fact that additive manufacturing technologies create a weight advantage by reducing the number of assembled parts with monolithic production also plays an important role in attracting so much attention.

Especially in the aerospace industry, materials with geometric difficulties in the production of aircraft engine components can be easily produced by using additive manufacturing methods that allow structural optimization. At this point, while the physical and chemical properties of the materials to be used in additive manufacturing play an important role in the quality of the geometries produced, the knowledge of how these materials are produced and used is of strategic importance.